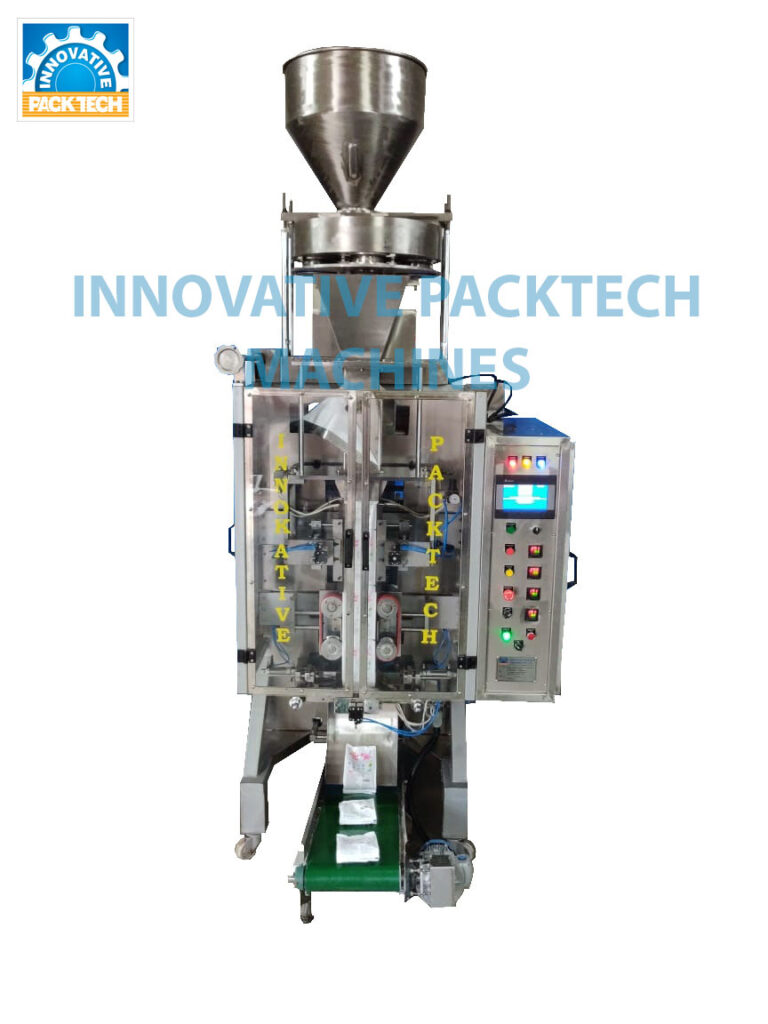

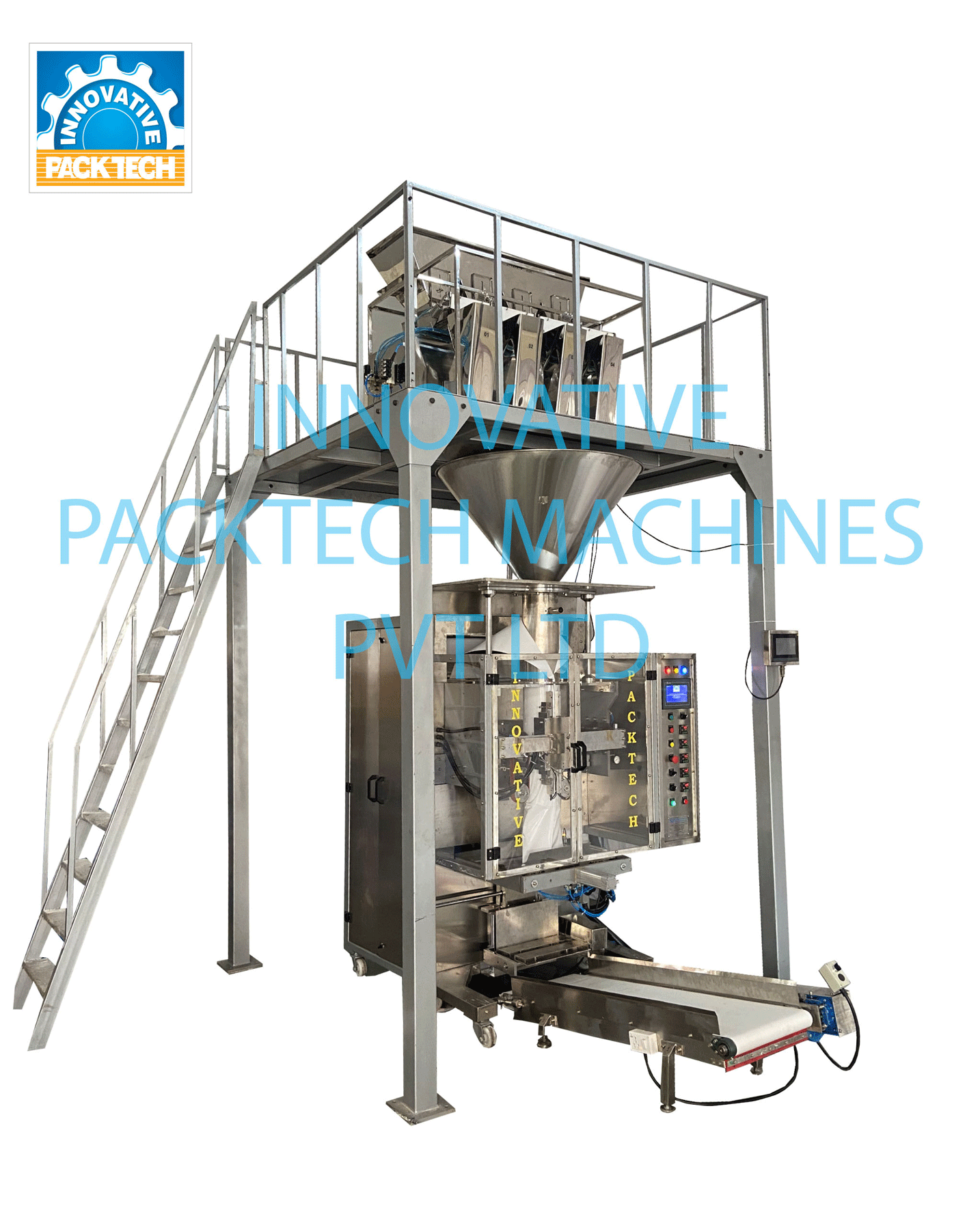

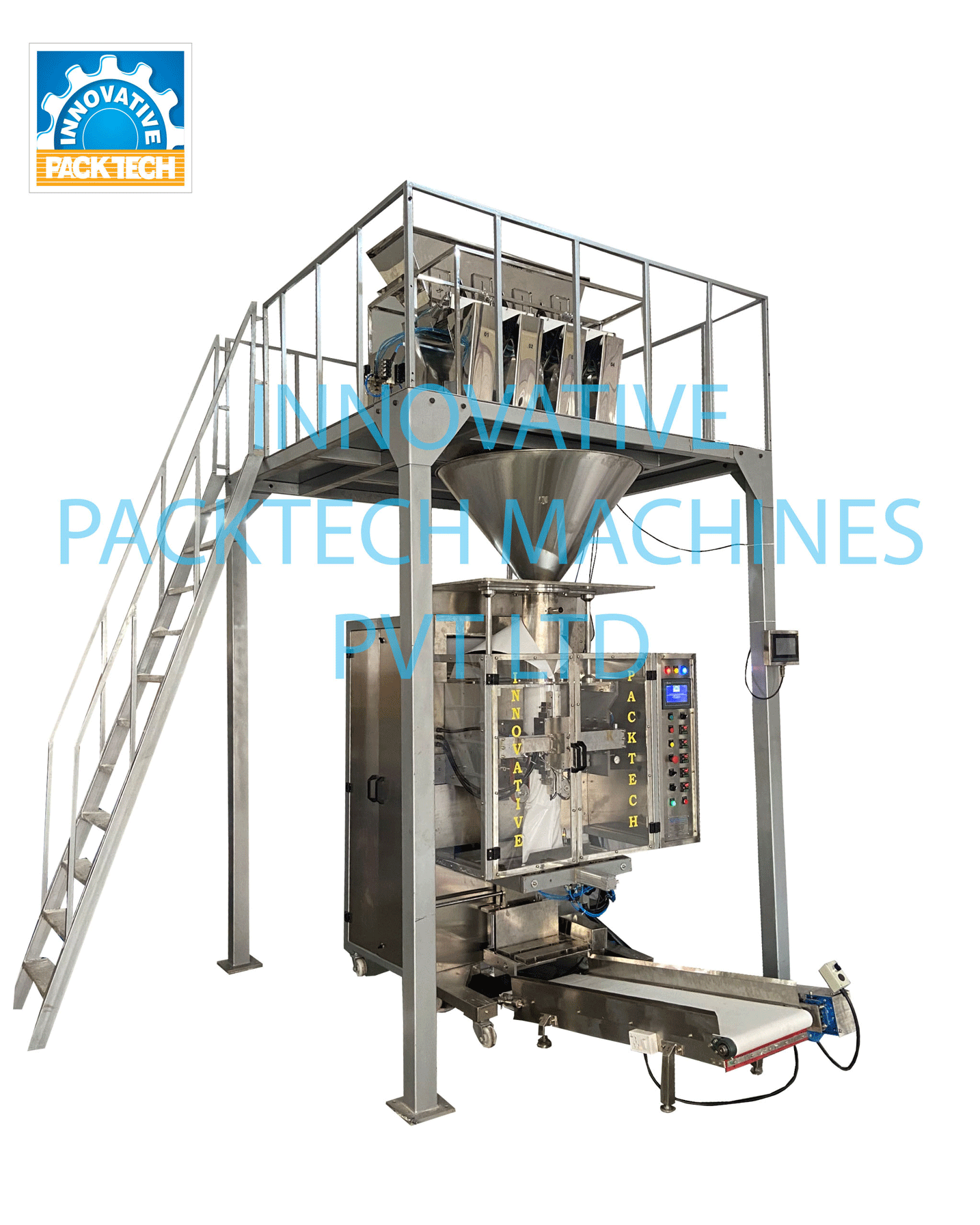

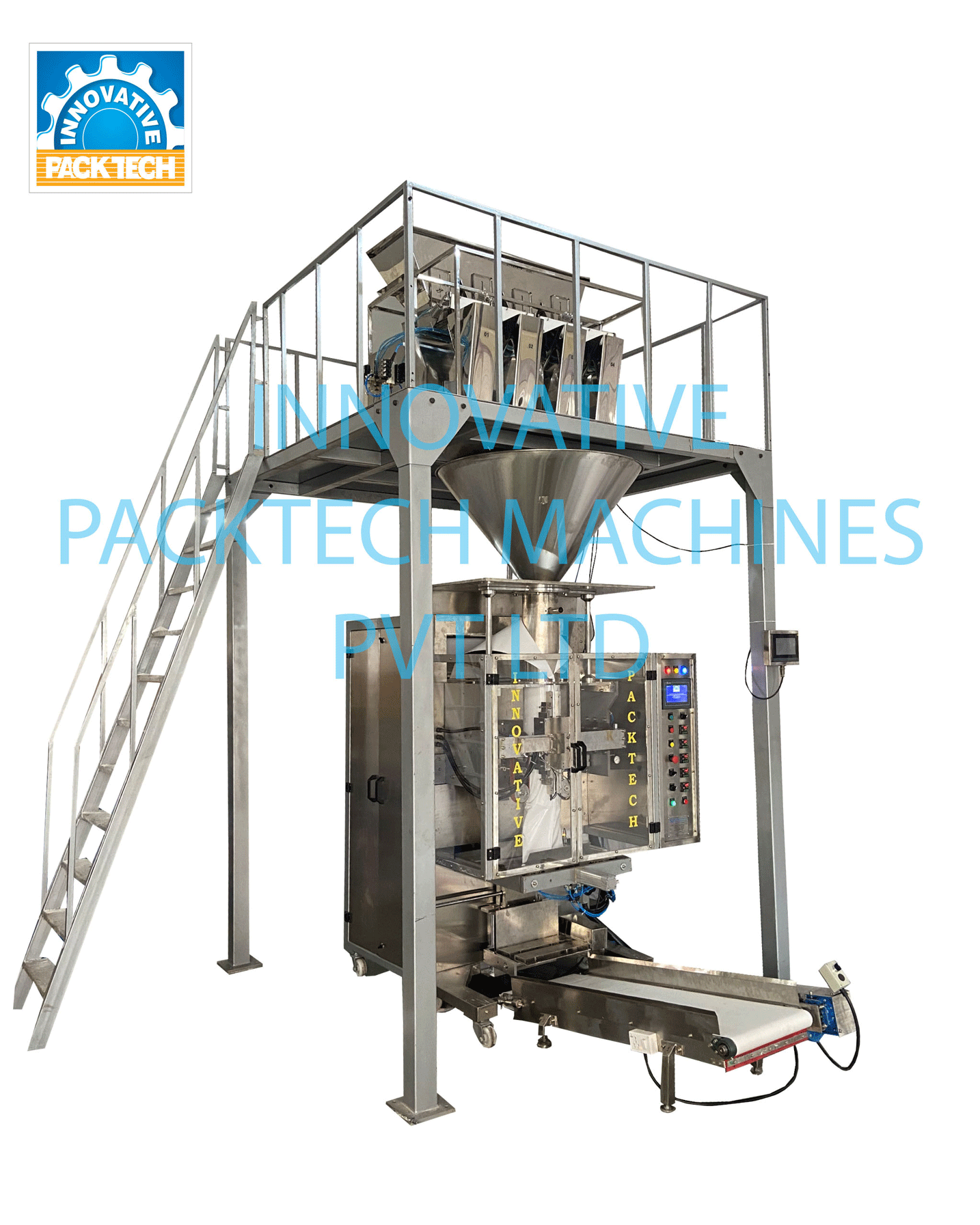

Innovative PackTech: A Leading Manufacturer and Supplier of Collar Type Packing Machines in Delhi

When it comes to the packaging industry, efficiency, accuracy, and reliability are crucial factors that can make or break a business. In this competitive market, Innovative PackTech stands out as one of the best manufacturers and suppliers of Collar Type Packing Machines in Delhi.

With a strong commitment to innovation and quality, Innovative PackTech has earned a reputation for delivering top-notch packaging solutions to businesses across various industries. Their Collar Type Packing Machines are designed to optimize the packaging process, providing seamless performance and exceptional results.

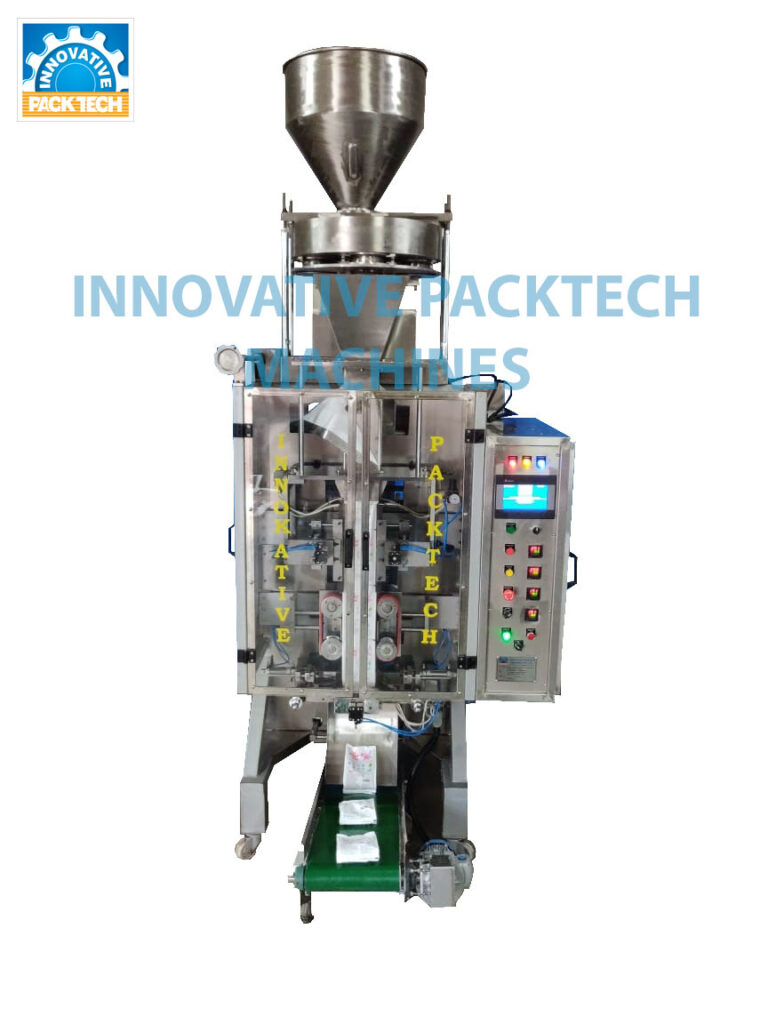

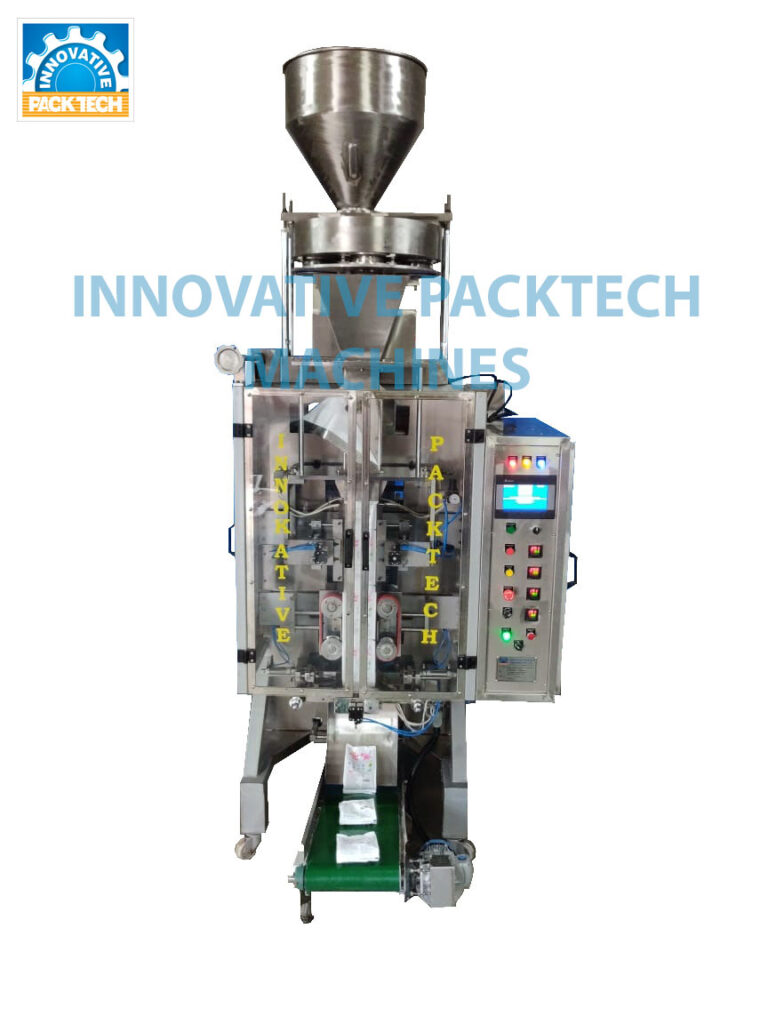

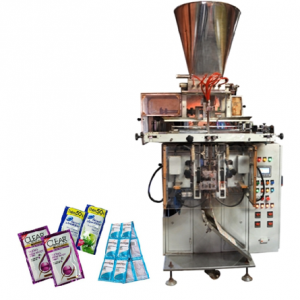

What sets Innovative PackTech apart from the competition is their relentless pursuit of excellence in every aspect of their products. Their Collar Type Packing Machines are built with cutting-edge technology, ensuring precise and consistent packaging. These machines are capable of handling a wide range of products, from food items to pharmaceuticals, and can accommodate different packaging materials such as laminates, films, and pouches.

The Collar Type Packing Machines from Innovative PackTech are known for their user-friendly interface, allowing operators to easily set up and control the packaging process. With features like adjustable speed, temperature control, and automatic filling systems, these machines offer unparalleled convenience and efficiency. Furthermore, their robust construction and high-quality components guarantee durability and minimal maintenance requirements.